In a new press release, Apple goes in-depth on how it has leveraged 3D printing in the manufacturing process of this year’s Apple Watch Series 11 and Apple Watch Ultra 3.

For the first time, both models are made with 100 percent recycled aerospace-grade titanium powder, something Apple says was “not previously considered possible at scale.”

The manufacturing breakthrough has led to significant improvements in the environmental impact of Apple Watch production.

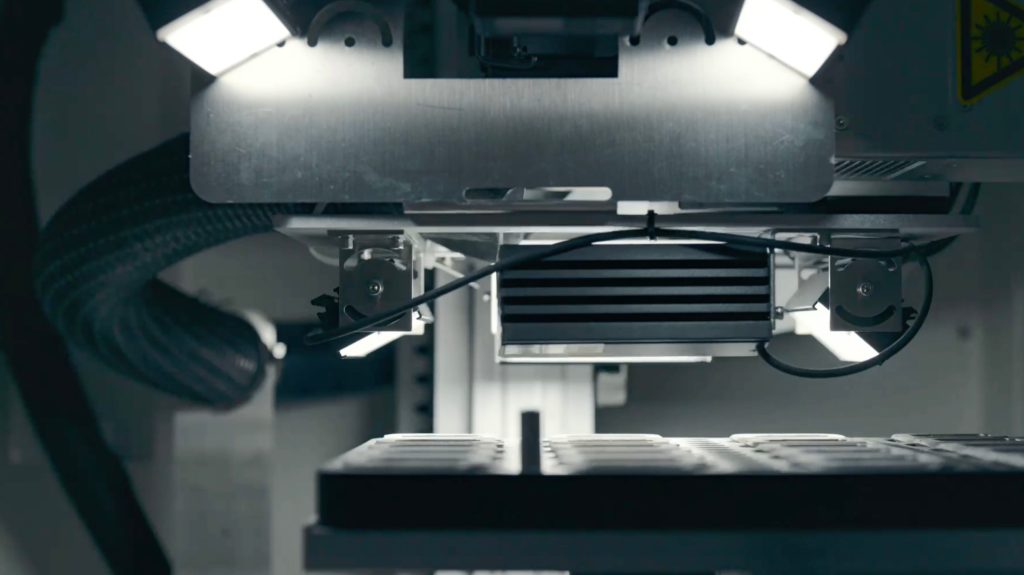

Using 3D printing to make Apple Watch

Apple explains that it had to strike a balance between perfecting the use of 3D printing while retaining the durability and design elegance of the Apple Watch:

This year, all Apple Watch Ultra 3 and titanium Apple Watch Series 11 cases are 3D-printed with 100 percent recycled aerospace-grade titanium powder, an achievement not previously considered possible at scale. Every team at Apple rallied behind a shared ambition. The polished mirror finish on Series 11 had to be pristine. Ultra 3 had to maintain its durability and lightweight form to meet the demands of everyday adventurers. They both also had to be better for the planet without compromising performance, and use the same or better-quality materials.

The press release continues:

Using the additive process of 3D printing, layer after layer gets printed until an object is as close to the final shape needed as possible. Historically, machining forged parts is subtractive, requiring large portions of material to be shaved off. This shift enables Ultra 3 and titanium cases of Series 11 to use just half the raw material compared to their previous generations.

Apple says that this innovative process has led to raw titanium savings of more than 400 metric tons in 2025. Apple Watch Series 11 and Apple Watch Ultra 3 use 50% less raw material than previous generations.

“A 50 percent drop is a massive achievement — you’re getting two watches out of the same amount of material used for one,” explains Sarah Chandler, Apple’s vice president of Environment and Supply Chain Innovation. “When you start mapping that back, the savings to the planet are tremendous.”

Apple emphasizes that all of this goes towards its Apple 2030 goal of being carbon neutral across its entire footprint by the end of the decade. “Already, all of the electricity used to manufacture Apple Watch comes from renewable energy sources like wind and solar,” Apple says.

3D-printing also unlocked a key upgrade for the Apple Watch Series 11 and Apple Watch Ultra 3: an improvement in waterproofing for the antenna housing in cellular models.

Going beyond Apple Watch, Apple’s work in 3D printing allowed it to create a USB-C port thin enough for the iPhone Air’s 5.6mm chassis:

That design flexibility unlocked another benefit that goes beyond Apple Watch: the USB-C port on the new iPhone Air. By creating an entirely new port with a titanium enclosure that is 3D-printed with the same recycled titanium powder, Apple was able to make its incredibly thin yet durable design a reality.

The full press release can be found on Apple’s website. It’s a fascinating look into all the manufacturing techniques behind the scenes of the Apple Watch Series 11 and Apple Watch Ultra 3, as well as the resulting benefits.

My favorite Apple Watch links:

- Apple Watch Series 11

- Twelve South Butterfly 2-in-1

- Anker 3-in-1 Charging Station for iPhone, AirPods, and Apple Watch

- Nomad Titanium Apple Watch Band

- Apple Watch Ocean Band

Follow Chance: Threads, Bluesky, Instagram, and Mastodon.

FTC: We use income earning auto affiliate links. More.

Comments